Aluminum Oxide

Aluminum-Oxide is probably the most commonly used abrasive in the market today. It is a versatile abrasive that offers long-life, high-efficiency and affordability in one package.

Aluminum-Oxide (AO) is a man-made material created by combining bauxite with other materials and firing them in an oven. The resulting material is then crushed which creates the abrasive’s signature pyramid shaped grains. This shape, combined with the materials used in the mixture, give AO its durability.

Aluminum-Oxide is a great general-purpose abrasive because it is effective on so many surfaces, including soft and hard woods, most metals (especially steel), leather, etc.

Abrasive Industrial Supplies (AIS) has two main varieties of Aluminum-Oxide abrasive belts – AOJ and AOX. The AOJ belts have a J-weight cloth backing which is highly flexible. AOX belts have an X-weight cloth backing that is quite stiff. You can read a lot more about backing weights in our Abrasive Belt Backings blog post.

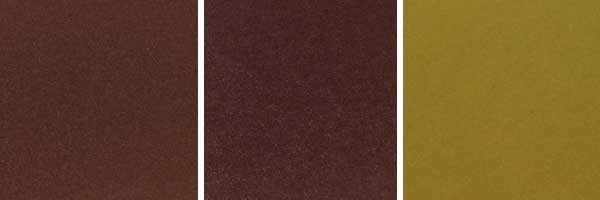

AO Belts are usually reddish-brown in color but as you can see from the photo above, other colors are also available as each manufacturer of bulk material puts their own spin on the abrasive.